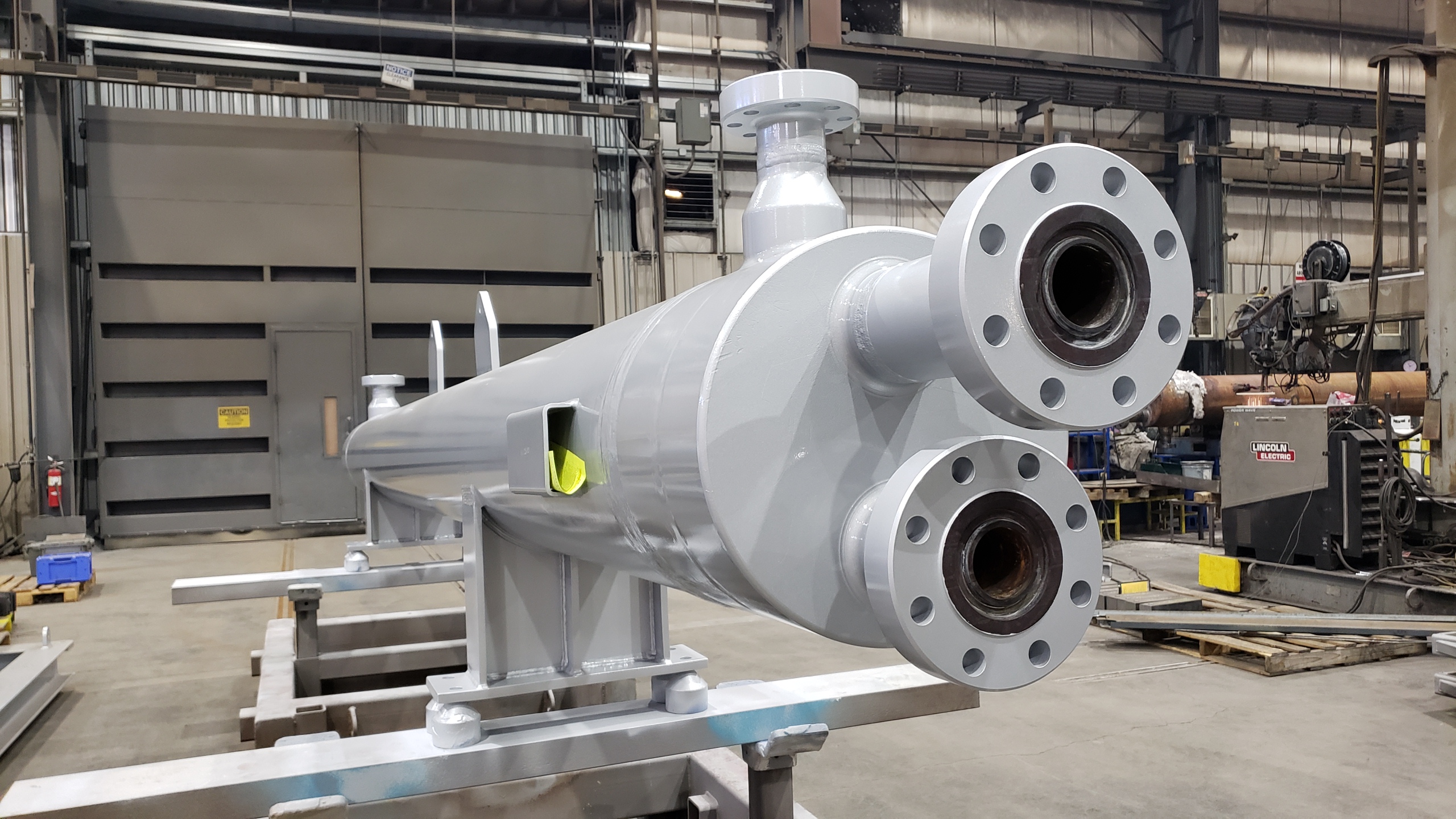

ASME Pressure Vessels

Springs Fabrication is recognized as an industry leading ASME Pressure Vessel manufacturer for high quality design, engineering, and fabrication of custom American Society of Mechanical Engineers (ASME) pressure vessels and heat exchangers in accordance with the ASME Boiler and Pressure Vessel code, Section VIII, Division 1, pressure vessels in accordance with ASME PVHO-1, Safety Standard for Pressure Vessels for Human Occupancy as well as our customer’s most stringent specifications. Our talented design and engineering team possess 35+ years of experience and code knowledge to design vessels and heat exchangers in the most cost-effective manner within the specified requirements.

Springs Fabrication`s strength is in the design and fabrication of specification intensive requirements. Serving most all industries, Springs Fabrication is the solution for high-quality and cost-effective manufactured solutions. Learn more on our Design and Engineering capabilities page.

Columns | Towers | Reactors | Autoclaves | Drums | Headers | Exchangers | Separators | Chillers | Scrubbers | Receivers | Condensers | Coalescers | Vacuum Chambers

The below list represents examples of our ASME Pressure Vessel Fabrication Design work:

- Blowdown tanks and blowdown drums

- Deaerators

- Water softeners and zeolite water softeners

- Ethylene loading drums and KO drums

- Suction scrubbers

- Molecular sieves dehydration units

- Air receivers and instrument air receivers

- Towers

- Reactors

- Propane storage tanks

- Flash tanks

- Fuel gas drains tanks

- Aqueous ammonia storage tanks

- Anhydrous ammonia storage tanks

- Heater tanks

- Drains tanks

- Closed cooling water head tanks

- Cooling water expansion tanks

- Steam turbine drain tanks

- Surge tanks

- Hydropneumatic surge tanks

- ASME tank

Materials Worked With:

Carbon Steel

CR-Mo

Clad Alloys

Stainless Steel

Aluminum

Nickel alloys, 200, 400, 600, 625, 800, 825

Hastelloy C276, B3, C22, C2000

Alloy 20

Alloy 718

AL6XN

Duplex and Super Duplex

Mechanical Design:

We provide complete mechanical design using Codeware’s Compress software. Our pressure vessels are designed and fabricated in accordance with ASME Section VIII, Div. 1, and the National Board Inspection Code (NBIC).

Pressure Vessel experience includes internal and external pressure conditions with various complex geometries and dimpled/conventional/half-pipe jackets.

Certifications:

ASME "U" Stamp - Certificate of Authorization to manufacture ASME pressure vessels

NBBI "R" Stamp - Certificate of Authorization to make repairs and alterations to ASME pressure vessels

NBBI "NB" Stamp - Certificate of Authorization to Register ASME pressure vessels with the NBBI